Production

It all begins with our

Larvikite Stones

Norway's heart, our foundation.

Deep in southern Norway lies the origin of our Larvikite stone - rare, resilient, and rich in character. Formed over millions of years, it fills every fireplace with a quiet strength and timeless beauty.

Selected by hand

Every Larvikite stone is handpicked on site - inspected for quality, size, and character. Only the most striking stones are chosen to become part of a LA\VIK Fireplace.

Water reveals their true character

Once selected, each stone is carefully washed to uncover its unique shimmer. The deep blues and silvery crystals of Larvikite only come to life with water. This process enhances the optical properties of the minerals, making the stone’s characteristic clearly visible.

Ready to take their place

Each selected and cleaned stone finds its place in our custom-fit box - ready to become part of your fireplace. Thoughtfully arranged. Carefully protected. Because details make the difference.

It goes on with the

Heat resistant glass

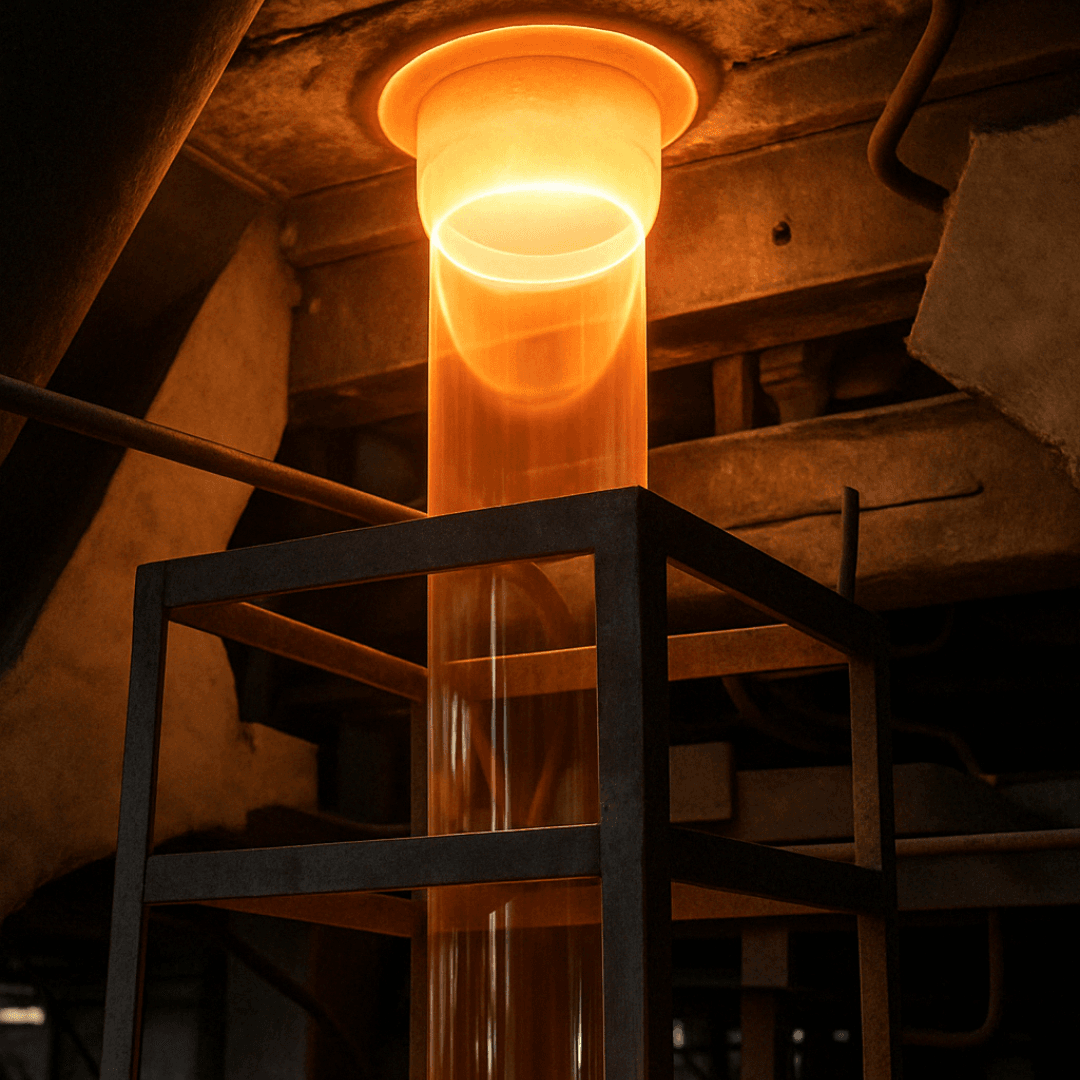

Tubing borosilicate glass

Our borosilicate glass is formed in long, glowing tubes with precision-crafted to withstand high heat and preserve perfect clarity. This ensures every piece remains flawlessly transparent, even after repeated use in high-temperature settings.

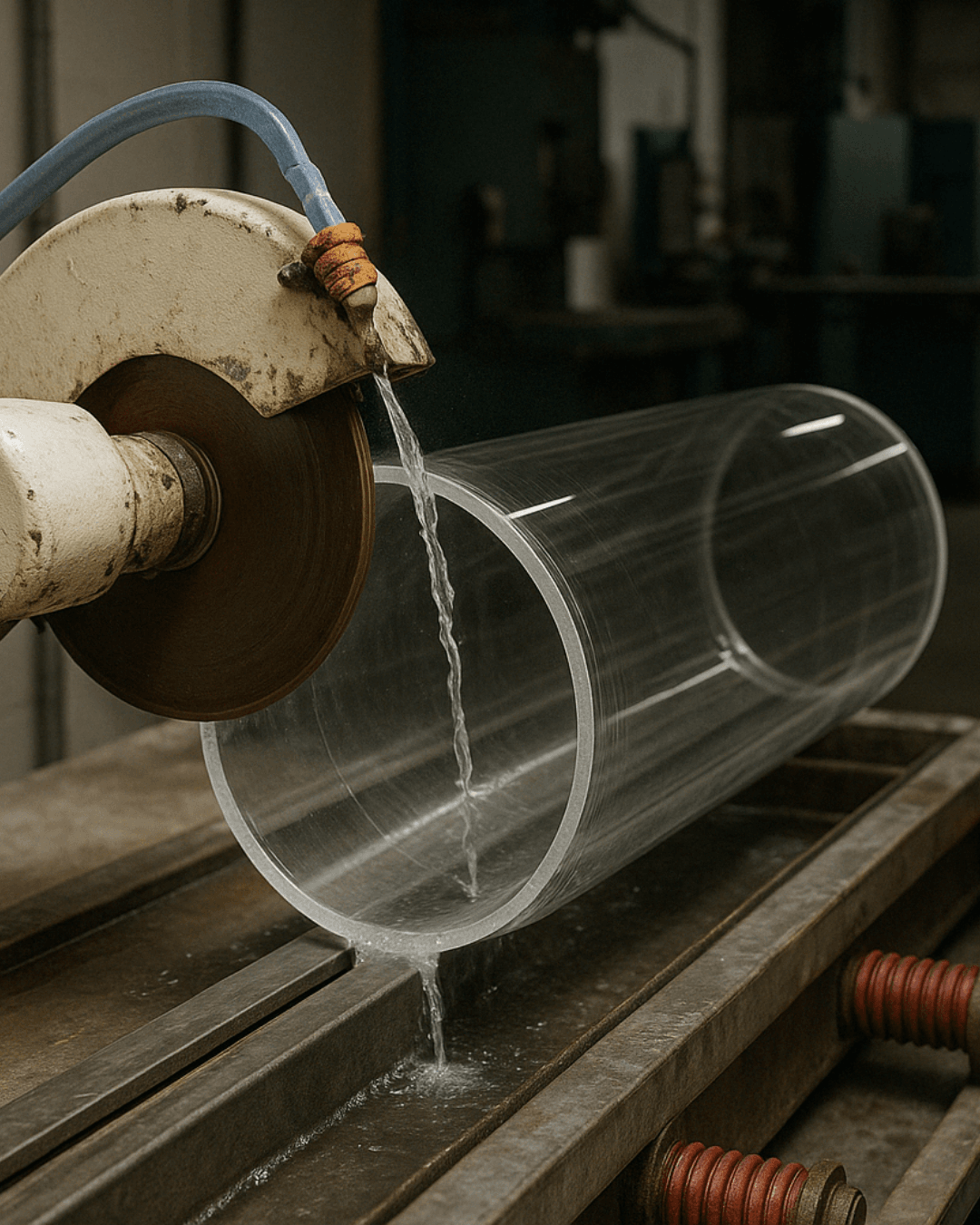

Cut the Glass

Each borosilicate glass tube is precisely cut to the perfect length. This ensures a flawless fit and enduring performance. The exacting tolerances minimize stress points, enhancing durability and structural integrity over time.

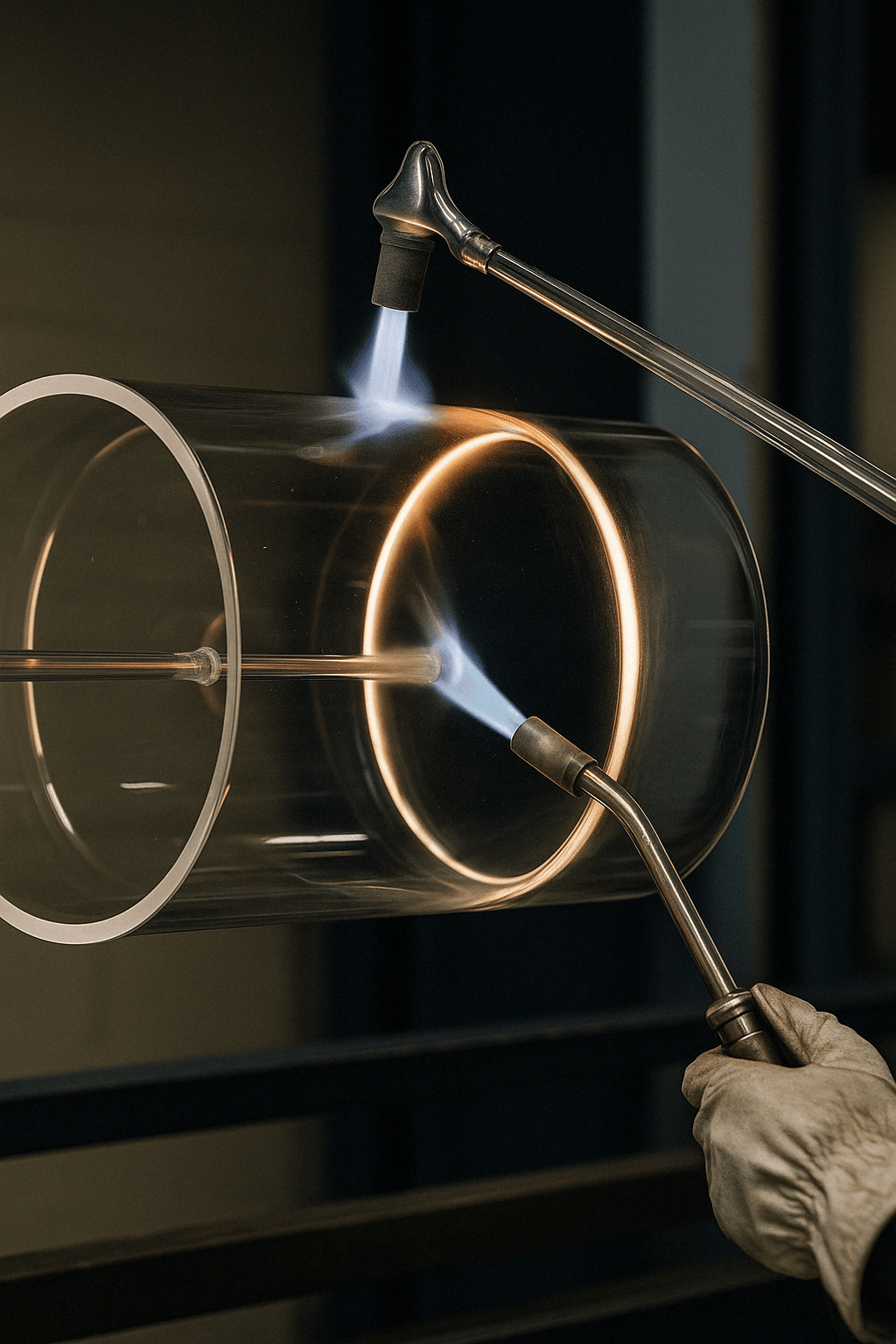

Fire polishing

To perfect the edges, each glass cylinder is fire-polished. The flame smooths the surface, adds strength and clarity, and brings out the final glow in every piece.

And continues with our

Stainless Steel

Melting stainless steel

Stainless steel begins as pure intensity, when its melted at extreme temperatures to unlock its full potential. It's the foundation of every frame: precise, enduring, and made to support the flame.

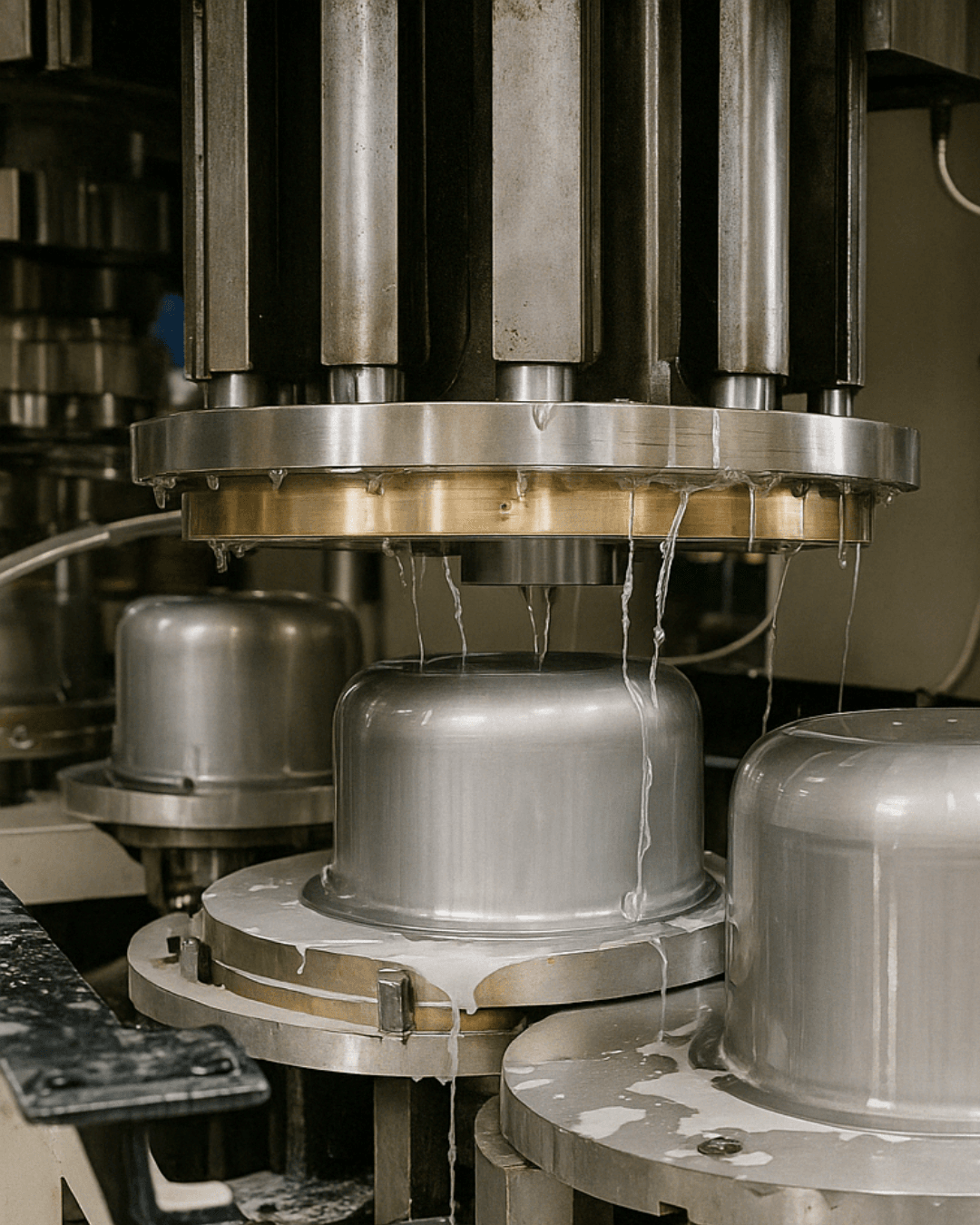

Deep drawing

In the deep drawing process, stainless steel is pressed into its final form using immense pressure and absolute precision. This cold-forming technique ensures every curve is seamless, strong, and built to last.

Our signature

We engrave each piece with our emblem as a mark of responsibility. It stands for the commitment to quality, longevity and design. A promise made visible in steel.

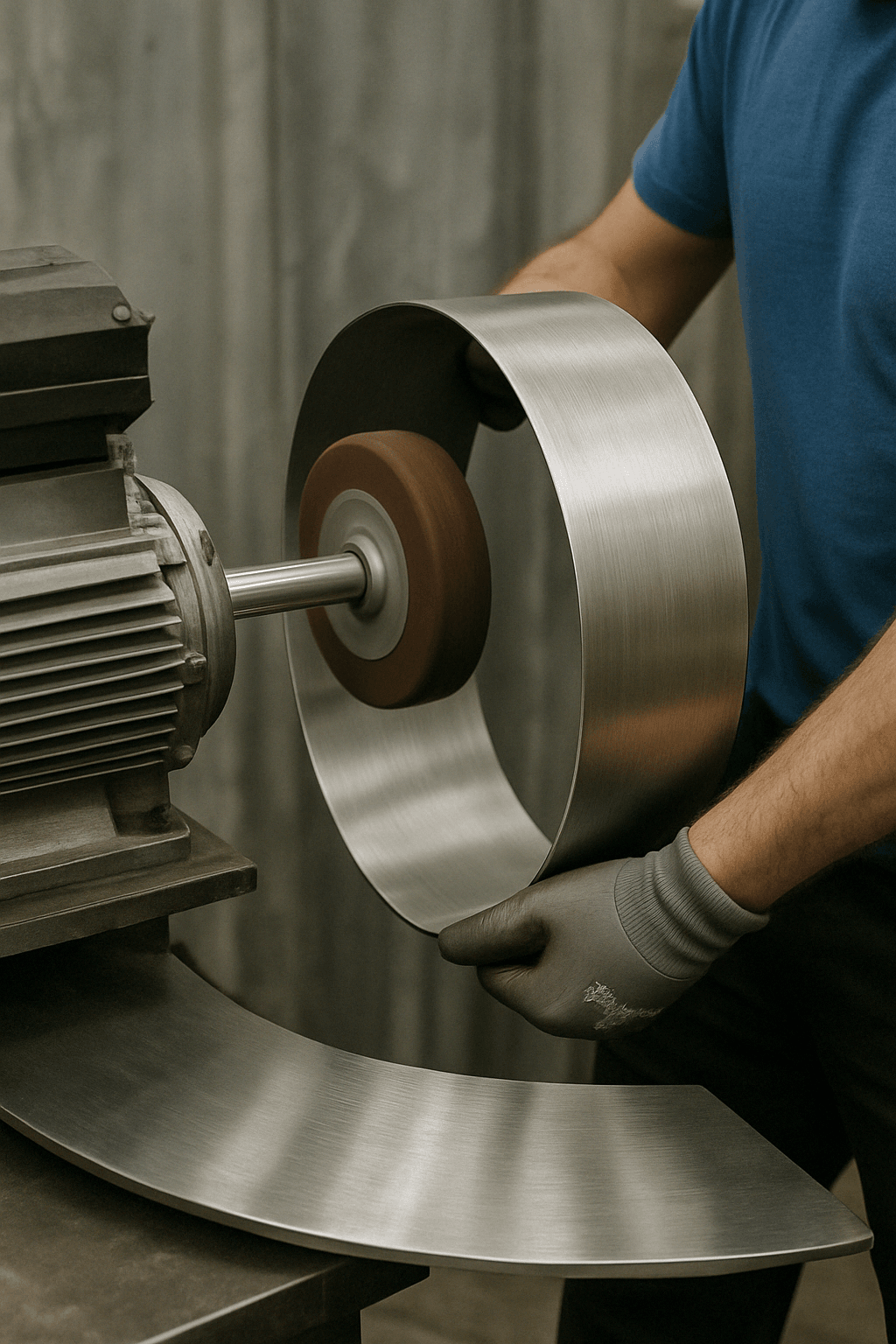

Rework and brushing

In the final stage, each steel surface is carefully reworked and brushed by hand. This process removes imperfections and gives the material its signature matte finish — smooth, clean, and quietly confident.

And the magic happens